Caliper Disc Brakes

Industrial and Off-Highway Uses. Do it All – Stop. Hold. Maintain Tension.

Experience W.C. Branham innovation. Each of our caliper disc brakes is made of either quality machined or cast aluminum construction and hardcoated for long service life. From a little as 600 to over 150,000 inch pounds of braking torque, our caliper disc brakes work perfectly for industrial and off-highway vehicular applications.

Pneumatic Brakes

Dynamic torque range from 70 to 693 lbf @ 100 PSI. Cast or extruded aluminum construction. Replaceable, non-asbestos friction pads. Multiple configuration options.

Hydraulic Brakes

Dynamic torque range from 70 to 693 lbf. (3082 N) per 100 PSI. Up to 1500 PSI maximum pressure. Replaceable, non-asbestos friction pads. Many disc diameter options (including unlimited). Multiple configuration options.

Mechanical Brakes

Cast or extruded aluminum construction. Hardcoated housings. Spring retractable piston(s). Replaceable, non-asbestos friction pads. Many disc diameter options (including unlimited).

Pneumatic Spring Applied Brakes

Multiple mounting options. Good for emergency brake applications. Models with 216 lbf (960 N) to 12,236 lbf (54,428 N) of tangential force. Under 100 PSI release pressure.

Hydraulic Spring Applied Brakes

Ideal for emergency stopping and holding of industrial machinery, and off-highway vehicles. Cast aluminum construction and hardcoated housings. Non-asbestos replaceable pads. Float mount with Belleville disc spring stack(s).

Dual Function Brakes

Hydraulic and mechanical force in one brake. Cast aluminum construction and hardcoated housings. Non-asbestos replaceable pads. Fixed or float mount with adjustable nut for pad wear.

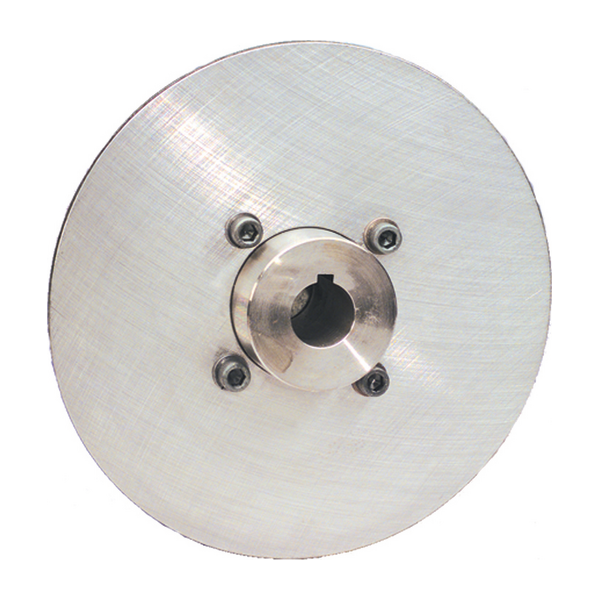

Brake Disc and Hub Assemblies

Blanchard ground 1010 carbon steel with 80 RMS finish. Many disc diameters. Choice of fixed or QD hubs including custom to your brake design.

Brake Repair Kits and Spare Parts

Friction pads, seal kits, and everything you need to keep your brakes working better longer.